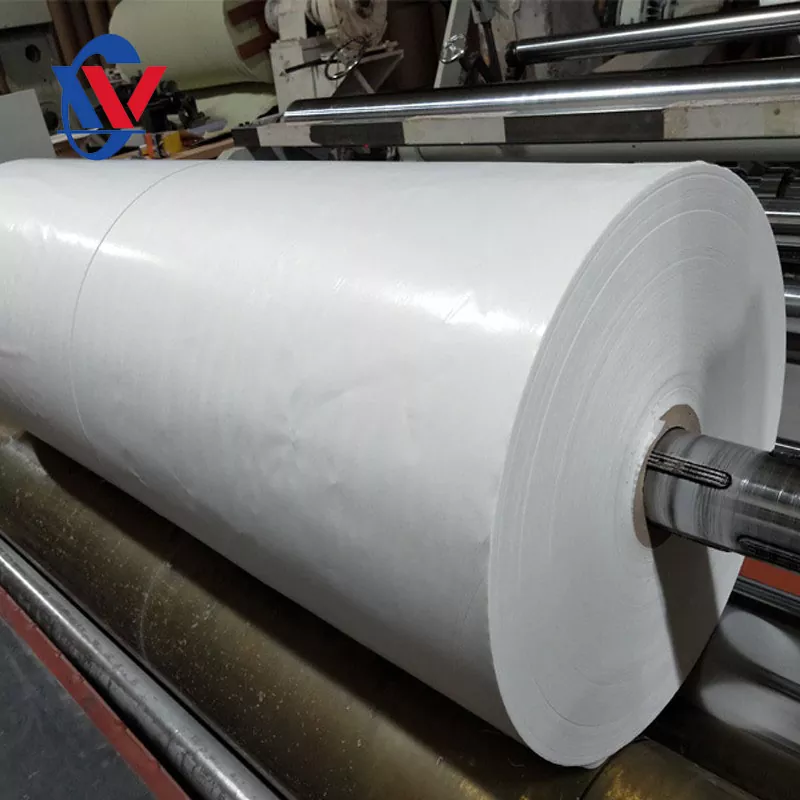

Laminated White Kraft Paper

Send Inquiry

Laminated white kraft paper is a composite material made by coating a layer of plastic film on the surface of white kraft paper. This material combines the writing properties of paper with the waterproof, oil-proof and moisture-proof properties of plastic, and is widely used in various packaging fields.

Features

Laminated white kraft paper has the following main characteristics:

Oil-proof and waterproof: By coating a layer of plastic film on the surface of paper, it can effectively prevent the penetration of grease and water, and is suitable for packaging needs that require oil and water resistance.

Environmentally friendly and sustainable: Adopting FSC-certified raw white kraft paper substrate to ensure that the raw materials come from sustainably managed forest resources, supporting environmentally friendly procurement and circular economy.

High barrier performance: The synergistic effect of the plastic film layer and the paper base significantly improves the burst resistance and tear resistance of the bag body, and extends the service life of the packaging in storage and transportation.

Application scenarios

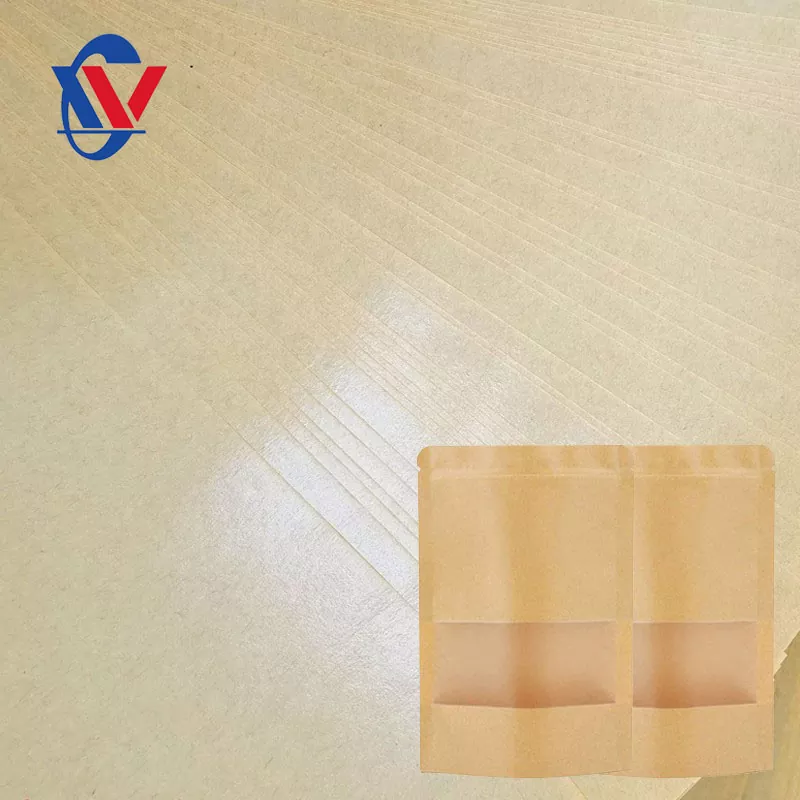

Laminated white kraft paper is widely used in the following fields:

Food industry: Suitable for packaging that requires oil and moisture resistance, such as cakes, cooked food, and takeout. Retail sector: Meet the dual demands of high-end brands for environmentally friendly packaging in terms of visual texture and functionality.

Industrial packaging: Applicable to areas such as hardware and chemical products that have strict requirements for waterproof barrier.