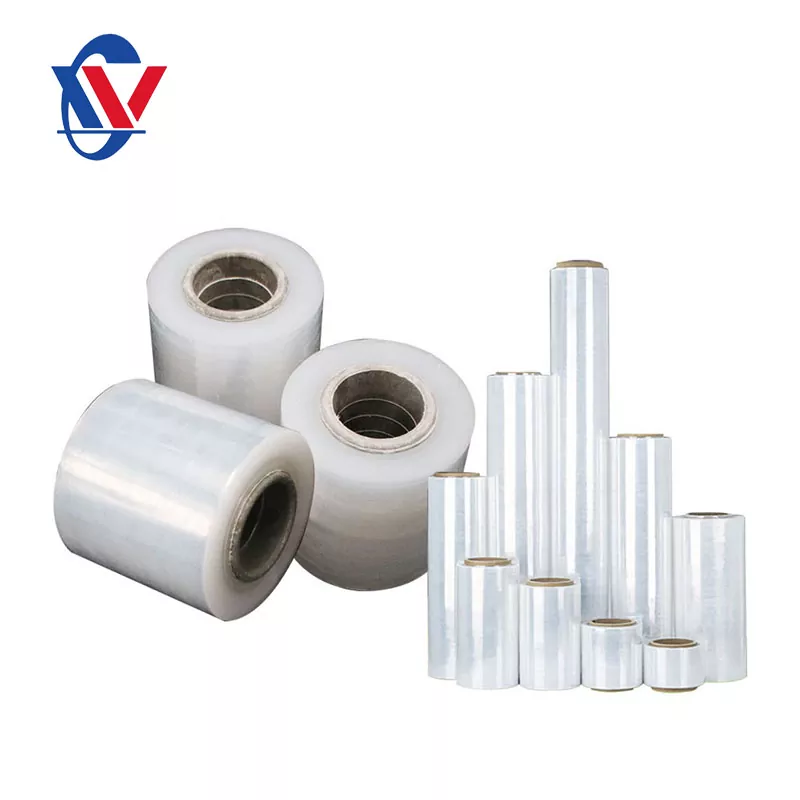

Industrial Stretch Film

Send Inquiry

Industrial stretch film is a roll-shaped packaging material, also known as stretch film and heat shrink film. It is mainly made of PE raw materials and usually contains a paper tube for easy use and handling.

Self-adhesiveness: It is sticky on one or both sides and can stretch and wrap the wrapped items tightly, but the stickiness will not adhere to the surface of the wrapped items, but only exists on the surface of the film.

Environmental protection: Industrial stretch film is safe and environmentally friendly, and is often used for food and drug packaging, but it should not be used for food and drug packaging again after long-term use.

High transparency: It is easy to identify the wrapped items and reduce delivery errors.

High tensile strength: This is one of the biggest characteristics of stretch film packaging. With the help of the film's super strong wrapping force and retraction. This is one of the biggest characteristics of stretch film packaging. With the help of the film's super strong winding force and retraction.

Primary protection: Primary protection provides surface protection for the product, forming a very light, protective appearance around the product, thereby achieving the purpose of dustproof, oilproof, moisture-proof, waterproof, and anti-theft. It is particularly important that the stretch film packaging makes the packaged items evenly stressed, avoiding damage to the items caused by uneven stress, which is something that traditional packaging methods (bundling, packaging, tape, etc.) cannot do.Primary protection provides surface protection for the product, forming a very light, protective appearance around the product, thereby achieving the purpose of dustproof, oilproof, moisture-proof, waterproof, and anti-theft. It is particularly important that the wrapping film packaging makes the packaged items evenly stressed, avoiding damage to the items caused by uneven stress, which is impossible with traditional packaging methods (bundling, packaging, tape, etc.).

Compression fixation: With the help of the retraction force of the wrapping film after stretching, the product is wrapped and packaged to form a compact, space-saving unit as a whole, so that the product pallets are tightly wrapped together, which can effectively prevent the mutual dislocation and movement of the products during transportation. At the same time, the adjustable stretching force can make hard products close together and make soft products compact, especially in the tobacco and textile industries. There is a unique packaging effect.

Cost saving: Using stretch film for product packaging can effectively reduce the use cost. The use of stretch film is only about 15% of the original box packaging, about 35% of heat shrink film, and about 50% of carton packaging. At the same time, it can reduce the labor intensity of workers, improve packaging efficiency and packaging grade.

Usage scenario

Industrial wrapping film is widely used in various industries, including foreign trade export, bottle and can making, papermaking, hardware and electrical appliances, plastics, chemicals, building materials, agricultural products, food, etc. It can be used not only for manual stretch film, but also for machine stretch film, and is suitable for centralized packaging of various goods.

Production process

Industrial stretch film is mainly made of mixed extrusion of several different grades of polyethylene resins, and has the characteristics of puncture resistance, high strength and high transparency. It wraps the goods stacked on the pallet to make the packaging more stable and neat, and has a super waterproof effect.