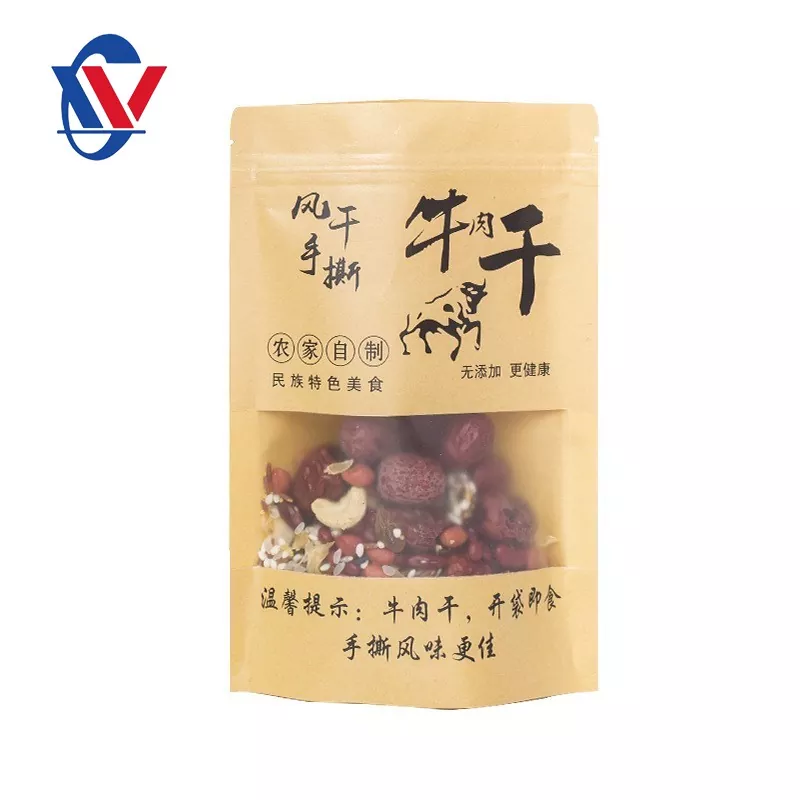

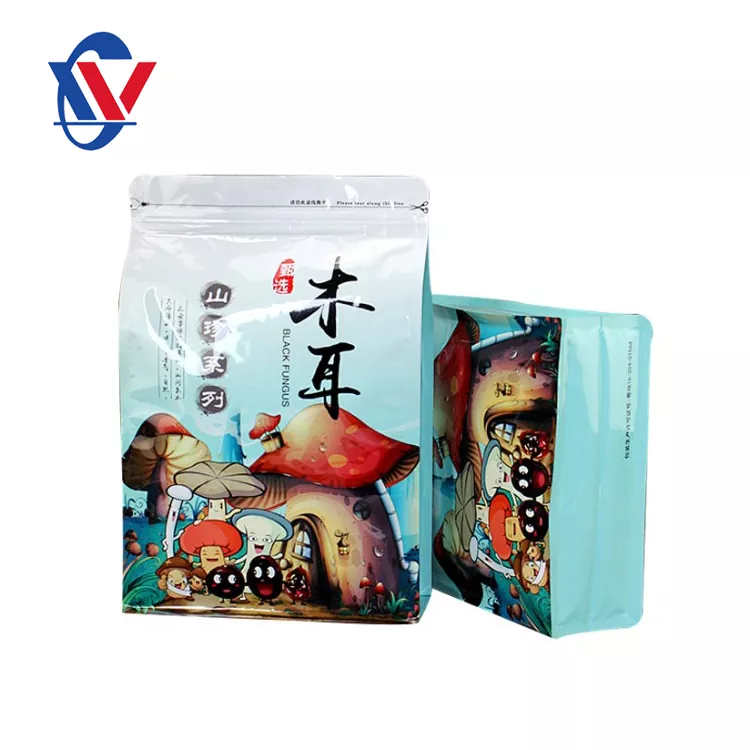

Kraft Paper Packaging Bags

Send Inquiry

Production process and raw materials

The main raw material of kraft paper packaging bags is kraft paper, which is mainly made of coniferous wood pulp (such as sulfate coniferous wood pulp) with long and tough fiber length. During the production process, it will undergo a series of process treatments such as cooking, washing, screening and bleaching to purify and strengthen the fiber properties, thereby producing high-quality paper that meets packaging needs.

Physical properties and application scenarios

Kraft paper packaging bags are widely used in the packaging field due to their high strength and good toughness. They can withstand large tension and pressure, and are suitable for packaging heavier items or for situations where they are squeezed and rubbed during transportation. Kraft paper packaging bags also have good air permeability and waterproof properties, and are suitable for packaging foods that need to breathe, such as fresh baked goods and tea. In addition, the versatility and environmental protection characteristics of kraft paper packaging bags make them widely used in many industries such as food, medicine, chemical raw materials, and building materials.

Environmental protection characteristics

The raw materials of kraft paper packaging bags come from renewable forest resources and have good degradability. In the natural environment, kraft paper bags can be degraded within a few months to a year, reducing pollution to the environment. In addition, kraft paper packaging bags meet national environmental protection standards, are non-toxic, odorless, and pollution-free, and are a low-carbon and environmentally friendly packaging material.

Our products are certified for high-standard markets with rigorous entry requirements like the EU, US, and Japan (see below). At the same time, we provide adaptable, cost-effective solutions for regions with varying needs. No matter your market, we are committed to delivering quality and value that works for you. Contact us today to find the perfect solution for your needs!