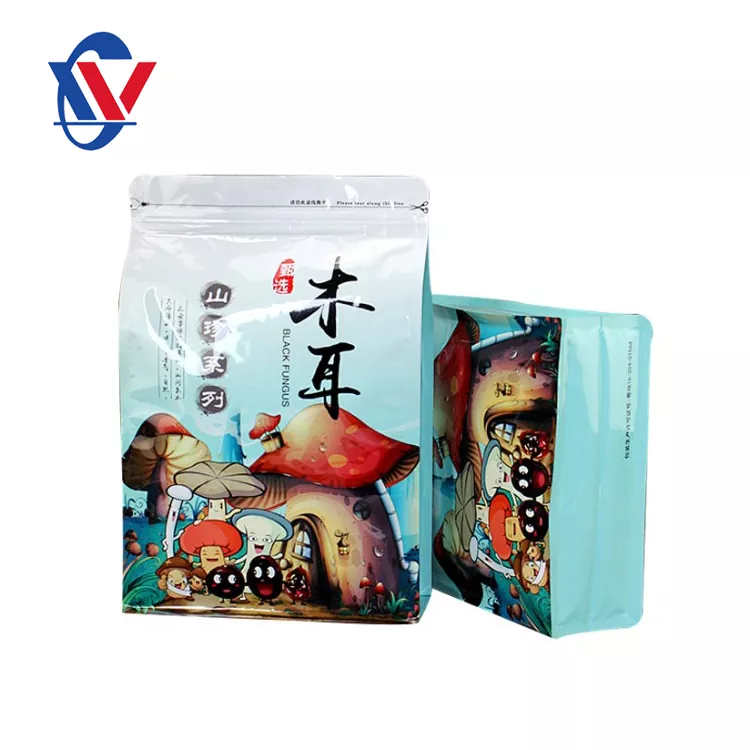

Candy and Chocolate Packaging Bag

Send Inquiry

Packaging form

Twist-type packaging: This is one of the oldest packaging forms, mostly used for candy, and can be completed by high-speed, automated vertical packaging machines or manual operations.

Pillow packaging: It became popular internationally in the 1970s and became popular in China in the 1980s. Due to the popularity of vertical packaging machines, most candy and chocolate manufacturers currently use pillow packaging.

Folding packaging: It is mostly used for chocolate products. Candy is suitable for roll packaging, strip packaging, and combined packaging. This packaging form has high requirements for packaging equipment and packaging materials.

Material selection

Candy and Chocolate Packaging Bag usually use plastic materials, such as polyethylene (PE) or polypropylene (PP). These materials have good sealing and moisture resistance, and can effectively protect candy from moisture and prevent adhesion. In addition, some high-end products may use color-printed packaging bags to increase the product's appeal and market value.

Common Problems and Solutions

In the high temperature environment of summer, agglomeration may occur in the candy packaging bag, mainly manifested as sugar particles sticking to each other to form lumps. This may be caused by reasons such as high warehouse temperature, insufficient ventilation, high candy moisture, unreasonable reducing sugar ratio or packaging film quality problems. Solving these problems can be achieved by improving warehouse environmental conditions, adjusting candy formulas and improving packaging materials.

Our products are certified for high-standard markets with rigorous entry requirements like the EU, US, and Japan (see below). At the same time, we provide adaptable, cost-effective solutions for regions with varying needs. No matter your market, we are committed to delivering quality and value that works for you. Contact us today to find the perfect solution for your needs!