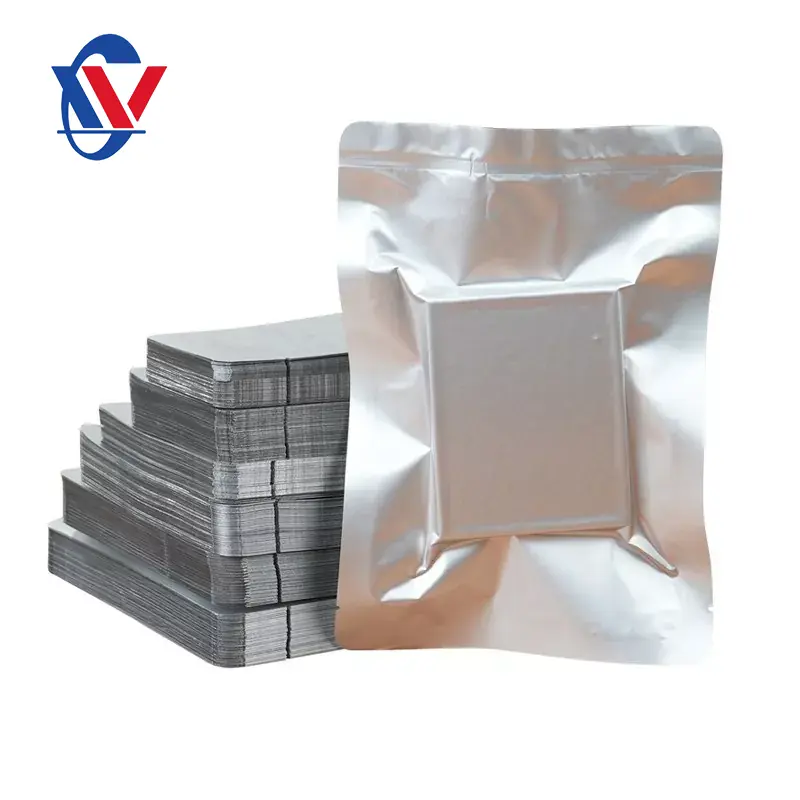

High Temperature Steamed Corn Bags

Send Inquiry

This High Temperature Steamed Corn Bags combine the advantages of canned containers and boiling water-resistant plastic bags, and can remain stable at high temperatures to ensure the safety and hygiene of food.

Materials and characteristics

The main material of high-temperature cooking corn bags is composite plastic film, which usually contains an aluminum foil layer to provide better insulation and high temperature resistance. This packaging bag can withstand high-temperature cooking at 121-135℃, ensuring that the food will not break or deform during high-temperature processing.

Application scenarios

High-temperature cooking corn bags are widely used in various food packaging that requires high-temperature processing, including:

·Concentrated juice, jam, vacuum aseptic packaging: long-term storage of concentrated juice and jam requires high-temperature treatment to ensure sterility and extend the shelf life.

·Aseptic packaging of fresh milk: stored at room temperature, the shelf life can reach 3 months.

·Packaging of cooked meat products: the shelf life can reach more than one month at room temperature.

·Condiment packaging: suitable for various condiments with unique flavors.

·Vacuum fresh-keeping small packaging for fresh livestock and poultry meat: inflatable fresh-keeping small packaging, which can be stored at room temperature for up to half a month.

·Purified water packaging: especially purified water for field operations and field operations.

·Premium baked goods, coffee, cereals, fried foods: These high-protein, high-fat foods require high-temperature processing to maintain their fragrant, crisp, puffy and crunchy characteristics.

Processing technology and design requirements

The design and processing of high-temperature cooking bags require special attention to the following points:

·Structural design: The structural design of the packaging bag should ensure that it will not break or deform at high temperatures, and usually adopts a multi-layer composite material, such as PET/PE/PA/AL/PA/PET structure.

·Processing technology: The temperature and time need to be strictly controlled during the processing to ensure that the material will not react chemically at high temperature, and at the same time ensure the sealing and insulation of the packaging

The cooking packaging bag is described in detail as follows:

1. Packaging type: A. Vacuum bag, B. Three-side seal, C. Four-side seal, D. Pillow bag

2. Contents: cooking bag, chestnut packaging, hot pot base, braised meat products, pre-prepared dishes, etc.

3. Material: ①BOPA+RCPP; ②BOPA+AL+LDPE; ③PET+BOPA+RCPP; ④PET+AL+BOPA+RCPP; ⑤Customization

4. Printing process: gravure printing

5. Printing ink: benzene-free and ketone-free ink

6. Features: moisture-proof, light-proof, puncture-resistant, cooking-resistant, high barrier, exquisite printing, good shelf display effect

7. Minimum order quantity: calculated according to the actual product specifications of the customer

Our products are certified for high-standard markets with rigorous entry requirements like the EU, US, and Japan (see below). At the same time, we provide adaptable, cost-effective solutions for regions with varying needs. No matter your market, we are committed to delivering quality and value that works for you. Contact us today to find the perfect solution for your needs!