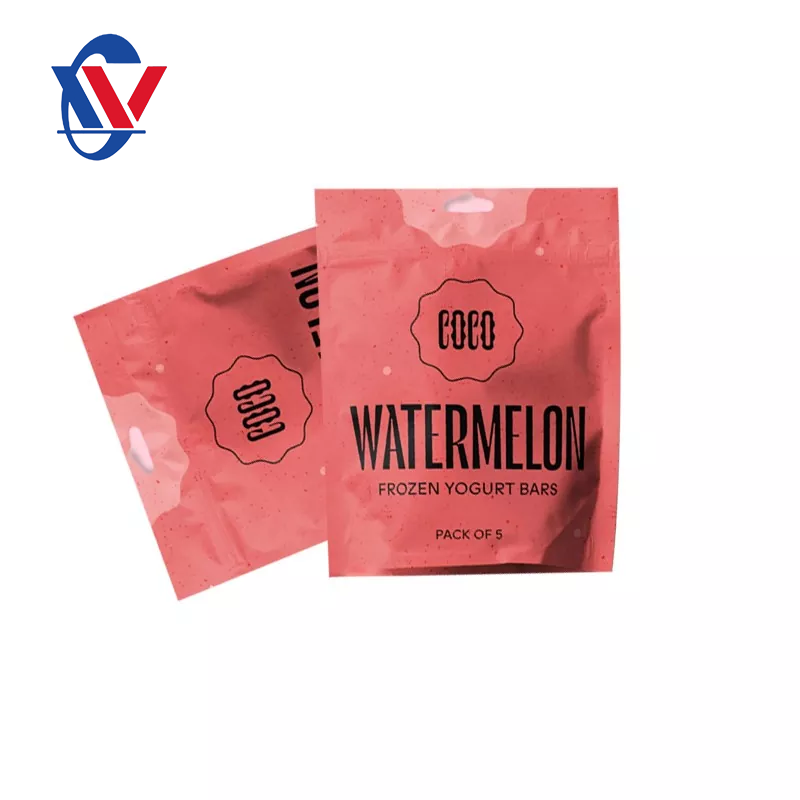

Snack Food Packaging Bags

Send Inquiry

Snack packaging bags refer to packaging materials used to package snack foods. Common types include paper bags and plastic bags. Paper bags and PP plastic bags are widely popular in the market.

Paper bags: Usually used to package snack foods such as dried fruits and nuts. Paper bags have good air permeability and moisture resistance, can maintain the freshness of food, and are environmentally friendly and recyclable.

Plastic bags: Common plastic packaging bags include PE (polyethylene) and PP (polypropylene) materials. These materials have good sealing and moisture resistance, and are suitable for the packaging of various snack foods, such as potato chips, biscuits, etc.

Materials and characteristics of snack food packaging bags

PE material: Plastic packaging bags made of polyethylene have good flexibility and puncture resistance, are suitable for the packaging of various snack foods, and can effectively prevent food from getting damp and deteriorating.

PP material: Plastic packaging bags made of polypropylene have excellent heat resistance and cold resistance, and are suitable for food packaging in high or low temperature environments, such as frozen foods.

Stand-up bag: This type of packaging bag can stand independently, making it convenient for consumers to use. It is often used for packaging jelly, pet food, etc.

Product features:

The product has high barrier properties, oil resistance, light blocking, fragrance preservation, and freshness preservation. It can be customized according to the size of the product.

The product meets environmental protection requirements, and the new printing process highlights the pattern design and trademark effect. Special trademarks or patterns can be designed to have a good anti-counterfeiting effect.

It can also highlight the high-end and unique shelf effect of the product.

Specifications and sizes: Made according to actual customer needs

Packaging type: A. Three-side seal, B. Eight-side seal, C. Four-side seal, D. Pillow bag

Contents: Potato chips/popcorn, snacks/snacks, biscuits/cakes, nuts/dried fruits, etc.

Material combination: ①BOPP+VMCPP/CPP; ②PET+VMPET+LDPE; ③BOPA+LDPE; ④PET+CPP; ⑤BOPP+VMPET+LDPE; ⑥Customized

Our products are certified for high-standard markets with rigorous entry requirements like the EU, US, and Japan (see below). At the same time, we provide adaptable, cost-effective solutions for regions with varying needs. No matter your market, we are committed to delivering quality and value that works for you. Contact us today to find the perfect solution for your needs!