Cup Cover Film

Send Inquiry

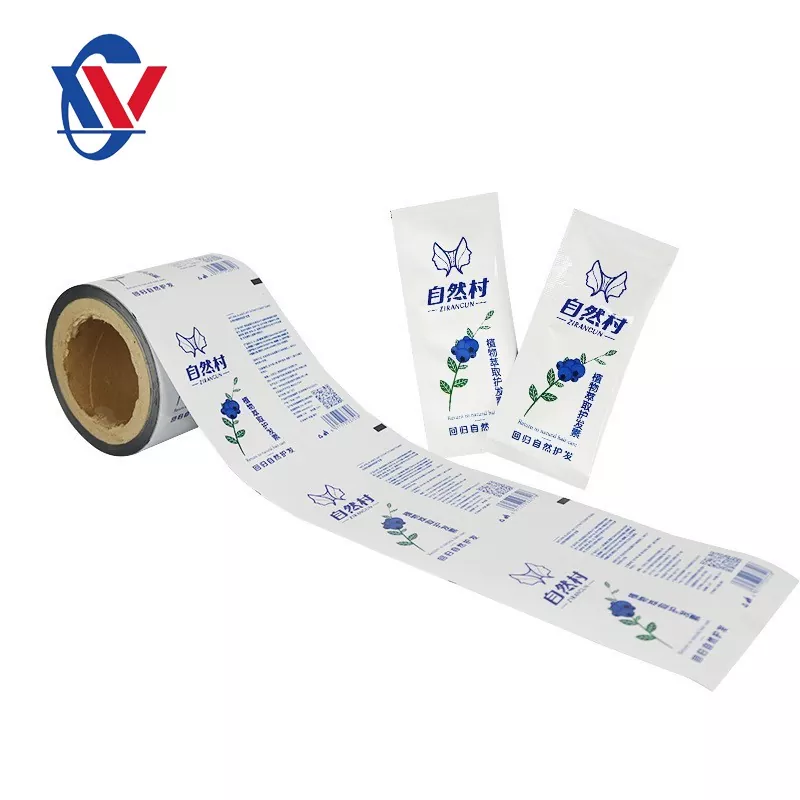

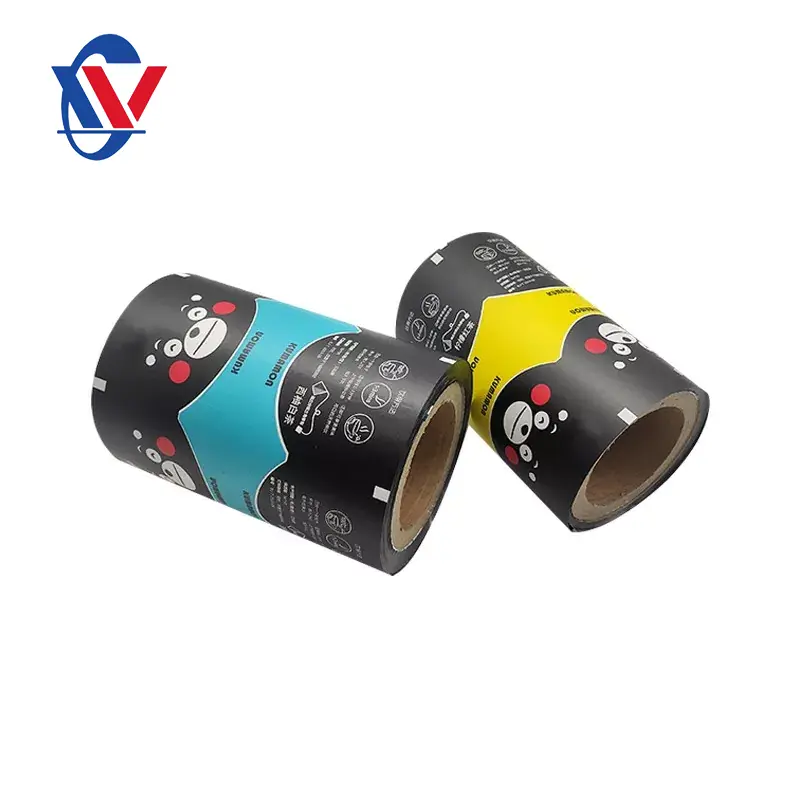

The composite in composite flexible packaging materials actually means lamination, which is to bond films or other flexible materials of different properties together, and then seal them to carry, protect and decorate the contents. The laminated structure of flexible packaging can be classified in many forms according to different combinations. But the conventional structure is usually distinguished by outer layer, middle layer, inner layer, adhesive layer, etc.

Material and characteristics

Cup cover film is usually made of polyethylene (PE) and other materials, and has the characteristics of waterproof and dustproof, pressure relief and exhaust, air pressure balance, high and low temperature resistance, etc. In addition, it has passed food grade certification, which is safer and more reliable to use.

Application scenario

Cup cover film is widely used in the packaging of various cups, especially in portable water-boiling cups. It releases internal air pressure through air holes to prevent water from overflowing and scalding after boiling. This design forms a one-way pressure-releasing and water-tight system, ensuring safety and convenience during use.

Our products are certified for high-standard markets with rigorous entry requirements like the EU, US, and Japan (see below). At the same time, we provide adaptable, cost-effective solutions for regions with varying needs. No matter your market, we are committed to delivering quality and value that works for you. Contact us today to find the perfect solution for your needs!