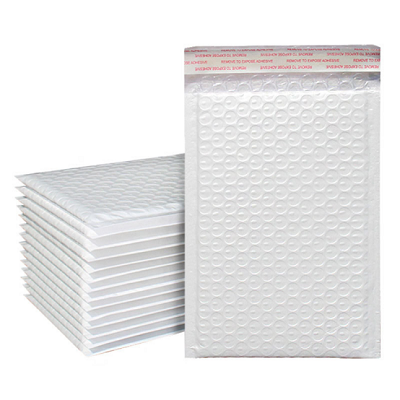

Bubble Bag

Send Inquiry

Material properties

Low-density polyethylene (LDPE) is the core material of Bubble Bag, and its properties include:

Physical properties: Density is 0.91-0.93 g/cm³, melting point is 110-115℃, processing temperature is 150-210℃, and it presents milky white translucent waxy particles.

Chemical properties: Alkali-resistant and resistant to general organic solvents, but poor grease resistance, and easy to age due to long-term exposure to ultraviolet rays or high temperatures.

Functional advantages: The air bubble structure is formed by the film containing air, providing protection functions such as shock absorption, wear resistance, and sound insulation, and also has thermal insulation effects.

Production process

The manufacture of bubble bags uses LDPE as raw material, and is mainly achieved through the following two high-pressure polymerization processes: Tube method: Reaction pressure 200 350MPa, single-pass conversion rate 20%-34%, and wide molecular weight distribution.

Aqueous method: reaction pressure 110 250MPa, single-pass conversion rate 20%-25%, narrow molecular weight distribution.

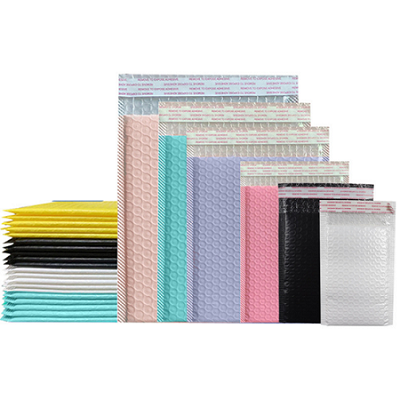

Common types

According to differences in composite materials and uses, bubble bags are mainly divided into:

Bare bubble bags: made of pure LDPE bubble film, high transparency.

Kraft paper composite bubble bag: the outer layer of kraft paper is easy to write and print, and the inner layer of bubble film is cushioning and shockproof.

Antistatic/static conductive bubble bag: through special treatment, the surface resistance value reaches 109-1011Ω, suitable for electronic product packaging.