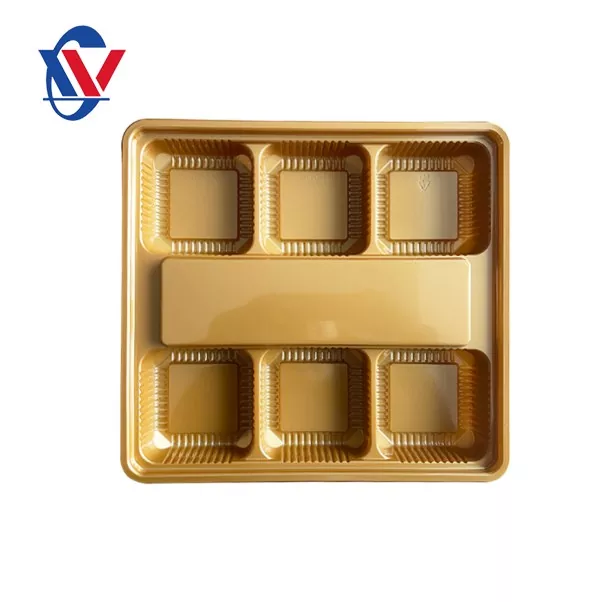

Blister Packaging Box

Send Inquiry

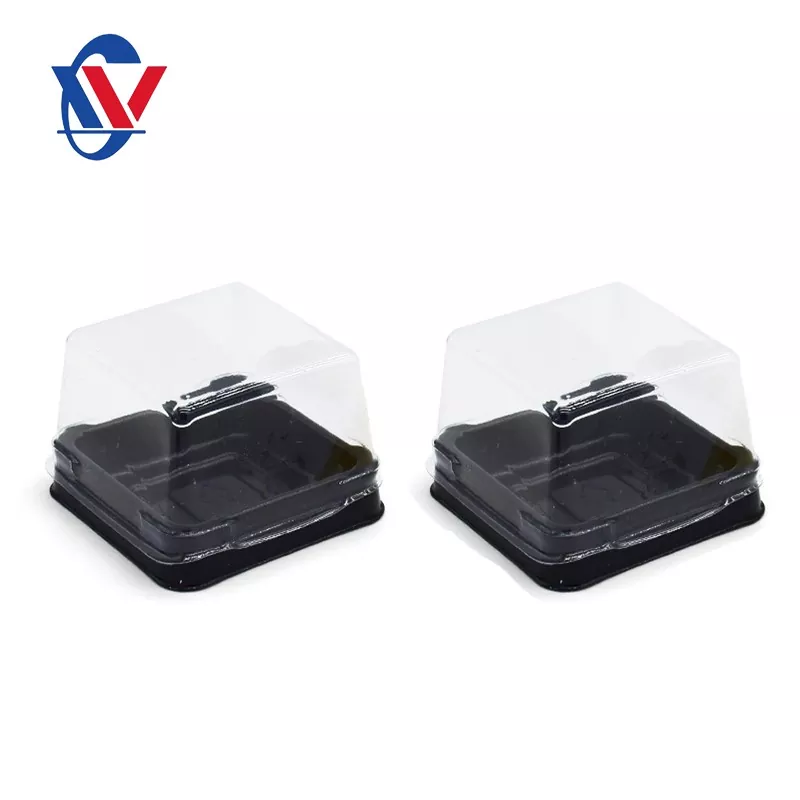

Uses of blister packaging boxesBlister packaging boxes are widely used in many fields such as food, medicine, cosmetics, electronic products and toys. Its high transparency can clearly display products and attract consumers' attention; at the same time, its light and easy to carry and environmentally friendly and recyclable characteristics also enable it to effectively protect products during logistics and storage.

Production process of blister packaging boxesThe production process of blister packaging boxes includes the following steps:

Mold making and processing: Make molds according to product design.

Mold treatment and drying: Make sure the mold is completely dry.

Softening treatment: Heat and soften the plastic sheet.

Vacuum forming: Place the softened plastic sheet in a vacuum chamber and form it by vacuum adsorption.

Cooling: Cool and fix the shape after forming.

Arrangement : Arrange and inspect the finished products.

Advantages and Disadvantages of Blister Packaging Boxes Advantages :

Lightweight and easy to carry : Blister packaging boxes are light in weight and easy to carry and store.

Strong protection : It can effectively prevent the product from being damaged during transportation and storage.

Low cost : The production process is automated, efficient and low cost.

Environmentally friendly and recyclable : The materials are recyclable and environmentally friendly.